Home > Blog > Planetary Gearbox-The Ultimate Guide to Boosting Efficiency & Profitability for Industrial Applicati

-

惠

Hi there! Welcome to my shop. Let me know if you have any questions.

惠

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Planetary Gearbox-The Ultimate Guide to Boosting Efficiency & Profitability for Industrial Applicati

2025-07-28 16:07:41

Introduction

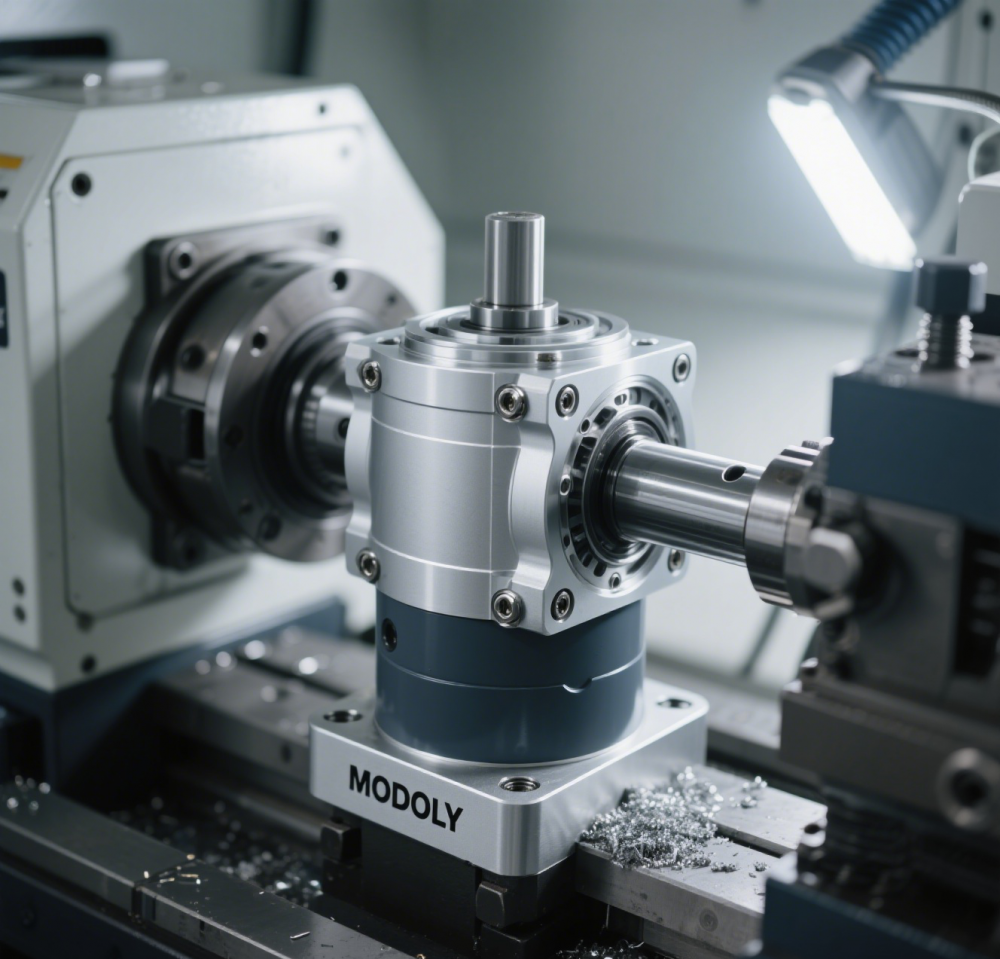

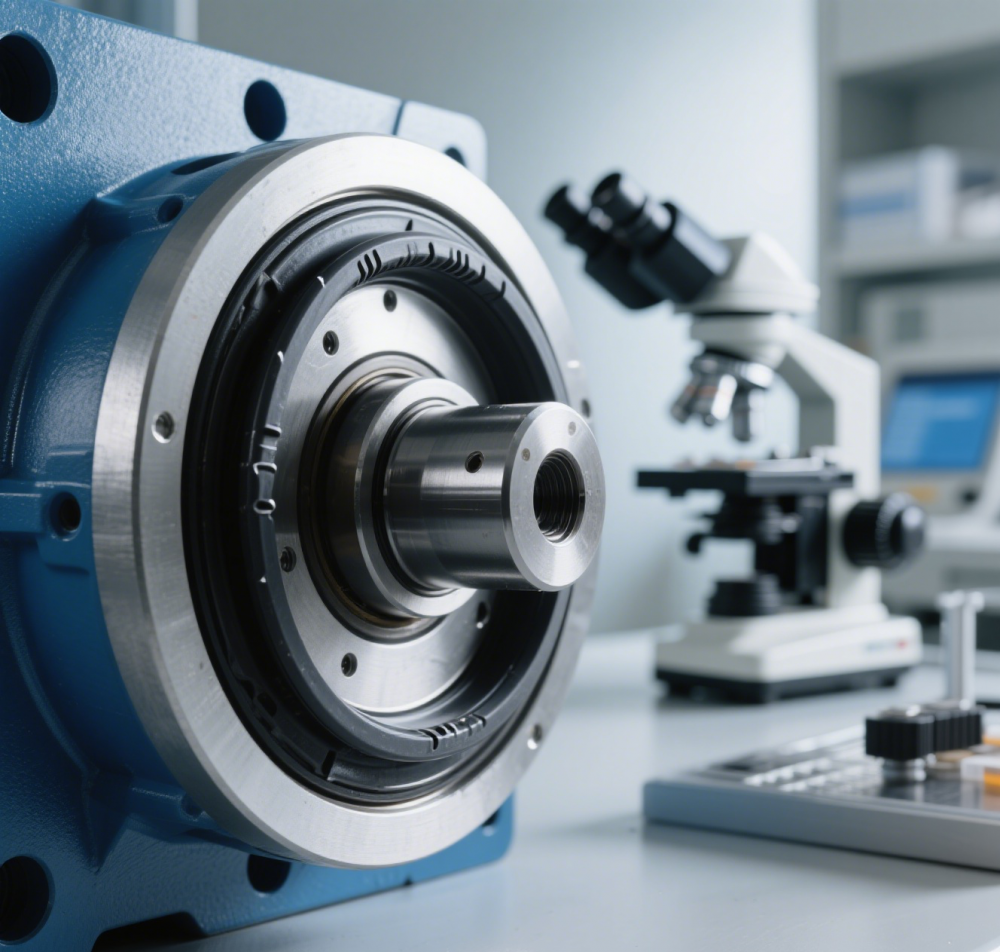

In today’s competitive industrial automation and precision machinery sectors, planetary gearboxes (planetary gear reducers) have become a critical component for enhancing equipment performance, reducing operational costs, and improving energy efficiency. With high torque density, precision backlash control, and long service life, planetary gear systems are widely used in robotics, CNC machines, packaging lines, and more.

This guide explores how planetary gearboxes optimize mechanical efficiency, reduce costs, and deliver a strong return on investment (ROI) for industrial businesses

1. The Role of Planetary Gearboxes in Improving Mechanical Efficiency: A Cost-Saving & Profitability Analysis

High Transmission Efficiency, Lower Energy Costs

Precision planetary gearboxes offer up to 97% efficiency, significantly reducing power consumption compared to traditional gear reducers.

Low backlash (≤1 arcmin) ensures precise motion control, minimizing vibration and wear

Compact & Lightweight Design Saves Space

Modular construction allows easy integration with servo motors and stepper motors, optimizing machine layout

Reduced Maintenance, Higher Reliability

Hardened alloy steel gears and precision grinding ensure long service life, lowering downtime and repair costs

2. Real-World Applications: How Planetary Gearboxes Cut Costs & Boost Profits

Industrial Robots: Precision Motion Control

Used in 6-axis robots & SCARA robots, planetary gearboxes ensure ±0.01mm repeatability, improving productivity

CNC Machines: Enhanced Cutting Stability

Integrated into rotary tables & tool changers, they provide high rigidity, reducing vibration for better surface finishes

Automated Production Lines: Smoother Conveyor Systems

Applied in packaging, printing, and sorting machines, they enable smooth acceleration/deceleration, reducing motor load

3. Economic Impact: How Planetary Gear Systems Optimize Performance & Reduce Costs

Lowering Total Cost of Ownership (TCO)

Smaller Motors Needed – High reduction ratios (5:1 to 100:1) allow using lower-power motors.

Extended Equipment Life – Precision gearing reduces shock loads, minimizing bearing & belt wear.

Higher Throughput – Stable transmission increases machine speed, boosting output.

ROI Case Study

An automotive parts manufacturer replaced worm gearboxes with precision planetary gearboxes, achieving

15% lower energy consumption

30% reduced maintenance costs

50% fewer breakdowns

4. Innovations in Planetary Gearbox Technology: The Future of Cost-Efficient Solutions

Latest Trends

Integrated servo planetary motors – Compact, high-response designs

Hybrid harmonic-planetary reducers – Zero backlash + high torque for semiconductor equipment

Smart monitoring – Vibration sensors for predictive maintenance

Material & Manufacturing Advances

Carburized & hardened gears – HRC60 hardness, 3x longer lifespan

Ceramic coatings – Reduced friction for high-speed applications

5. Case Studies: Real-World Cost Reduction & Profit Growth

5. Case Studies: Real-World Cost Reduction & Profit Growth

Case 1: Injection Molding Robot Speed Upgrade

Problem: High-backlash gearbox caused slow cycle times (6 sec/pick).

Solution: Installed precision planetary gearbox (≤1 arcmin backlash).

Result:

Cycle time reduced to 4.5 sec/pick (25% faster)

Annual production increased by 150,000 units (+$180K profit)

Case 2: Solar Wafer Cutting Machine Accuracy Boost

Problem: Traditional gearbox caused 8% defective wafers.

Solution: Upgraded to zero-backlash planetary gearbox.

Result:

Defect rate dropped to 2% ($500K annual savings)

Machine uptime increased from 8,000 to 12,000 hours

Conclusion: Upgrade to Planetary Gearboxes for Competitive Advantage!

Planetary gearboxes are not just components—they are strategic investments that improve efficiency, cut costs, and boost profitability. Whether in robotics, CNC machining, or industrial automation, they deliver measurable ROI

Take Action Now! Contact our enateam for a free gearbox optimization consultation and maximize your equipment performance

For more details please refer to the product:

https://www.modolycn.com/products/class/?27.html

Get the free sample,please contact

https://www.modolycn.com/page/contactus/index.php

Tags: reducer motor, planetary gearbox, speed gearbox