New trend in laser welding industry: market trends and opportunities worth hundreds of billions of y

1. Why will the demand for laser welding machines explode in 2024?

Data anchoring:

"According to the 2024 China Laser Industry Report, the penetration rate of laser equipment in the field of new energy battery welding has reached 72%, and the global market size will exceed US$22 billion in the next three years (CAGR 11.3%)."

(1)The fatal shortcoming of traditional processes

Arc welding/resistance welding: The heat-affected zone is large, resulting in a new energy vehicle battery module yield of less than 90% (laser welding can reach 99.5%+);

Labor cost: The monthly salary of a high-end welding technician exceeds 20,000 yuan, while a single laser welding machine replaces 3-5 people (calculated based on a 24-hour utilization rate).

(2) Policy and industry dual drive

Made in China 2025: Precision processing requirements force companies to upgrade equipment (such as medical device welding must comply with ISO 13485 standards);

New energy explosion: The demand for power batteries, hydrogen energy metal bipolar plates, etc. has surged, and laser welding has become a standard process.

Case: After a Dutch battery factory introduced a 6kW fiber laser welding machine, the welding speed of battery cell connectors increased by 300%, saving more than 8 million yuan in annual costs.

2. Three major technological breakthroughs of laser welding machines

(1)Overcoming the difficulty of welding high-reflective materials

Blue laser (wavelength 450nm): specializes in copper/aluminum welding, with an absorption rate of 65% (traditional infrared lasers are only 5%);

Composite welding solution: laser + arc composite, taking into account the speed and quality of thick plate welding (applicable to ships and heavy machinery).

(2) Intelligent upgrades to reduce the operating threshold

AI real-time quality inspection: automatic detection of weld pores and cracks through CCD visual system (such as Han's Laser Smart Weld system);

Digital twin: virtual debugging parameters first, then actual welding, reducing trial and error costs.

(3)Cost reduction promotes popularization

The price of domestic fiber lasers has dropped by 40% compared with 5 years ago (the share of Raycus Laser and Maxphotonics continues to grow);

The rise of leasing/time-sharing payment models has reduced the initial investment pressure of small and medium-sized enterprises.

3. How to choose laser welding equipment with high ROI? (Selection Guide)

(1) Comparison table of 4 core parameters

Demand scenario Recommended power Laser type Budget range (10,000 yuan)

Electronic precision welding (such as FPC) 50-300W Pulse laser 15-50

Power battery module welding 1-3kW Fiber continuous laser 80-200

High reflective material (copper/gold) 500W-1kW Blue light laser 150-300

(2)Pitfall avoidance guide

Trap 1: "Ultra-high power = better"? The actual material thickness needs to be matched (6kW welding 1mm thin plate may burn through);

Trap 2: Ignore the after-sales response speed (give priority to brands with local service outlets).

Expert advice:

"Ask the supplier to provide free proofing, test the tensile strength of the weld (refer to ISO 13919 standard), and calculate the comprehensive cost for 3 years (power consumption + maintenance + labor savings)."

4. Future trends: Who will seize the 100 billion market?

Ultrafast laser (picosecond/femtosecond): Breakthrough in welding of brittle materials such as glass and ceramics;

Green and low-carbon: Energy-saving laser (IPG launches YLS series with 30% lower energy consumption);

Integrated solution: Shift from stand-alone sales to "equipment + process package" (such as TRUMPF's Turnkey solution for photovoltaic welding ribbons).

5. Call to action (high conversion ending)

"Is your production line still troubled by low welding yield and high labor costs?

Click to get new solutions and product quotes: www.modolycn.com

Limited time appointment for free proofing

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

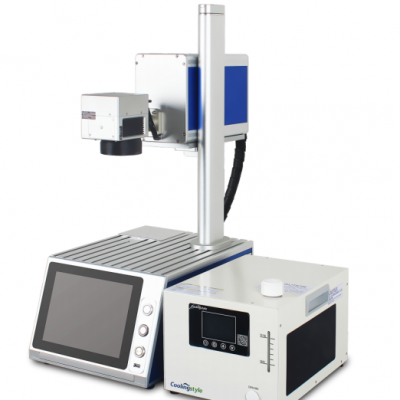

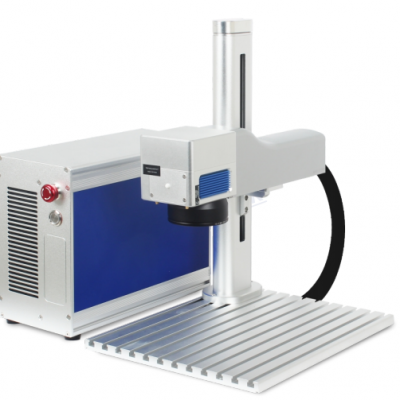

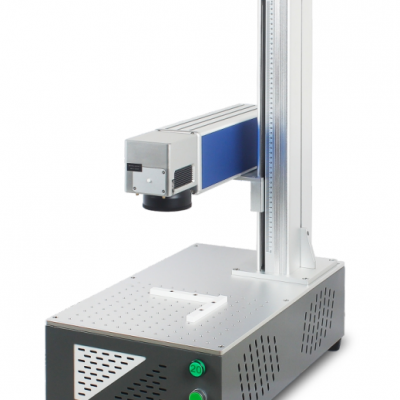

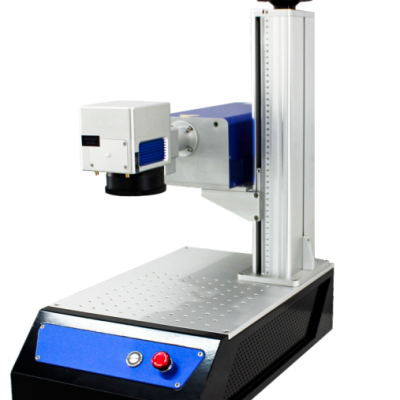

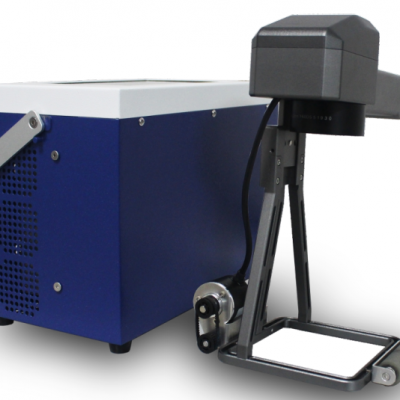

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More