How Laser Welding Machines are Revolutionizing the Automotive Industry

The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As

manufacturers seek faster, more precise, and eco-friendly production methods, laser welding machines have emerged as a game-changer.

From automotive body welding to battery assembly for electric vehicles (EVs), laser welding delivers unmatched efficiency, durability, and

cost savings.

✔ The latest laser welding machine innovations in car manufacturing

✔ Key benefits like high-speed welding, precision joining, and reduced material waste

✔ Real-world case studies of leading automakers using fiber laser welders

✔ A beginner’s guide to integrating automated laser welding systems

1. How Laser Welding Machines are Transforming Automotive Manufacturing

Why the Auto Industry is Switching to Laser Welding

Traditional welding methods like spot welding and MIG welding are being replaced by high-power laser welding machines due to:

✅ Faster production speeds – Laser welders operate at up to 100 meters per minute, reducing cycle times.

✅ Superior weld quality – Minimal heat distortion ensures stronger, cleaner joints in car body panels, exhaust systems, and EV battery

packs.

✅ Automation compatibility – Robotic laser welding systems integrate seamlessly with Industry 4.0 smart factories.

Case Studies: Automakers Using Laser Welding Successfully

Tesla – Uses fiber laser welding machines for aluminum battery casing assembly, improving structural integrity.

BMW – Implements laser hybrid welding for lightweight carbon fiber components.

Toyota – Adopts automated laser welding cells to enhance precision in chassis manufacturing.

2. Key Benefits of Laser Welding in Automotive Production

① Unmatched Precision & Strength

Laser beam welding achieves micro-level accuracy, crucial for sensor housings and electrical connections.

Non-contact welding reduces contamination, perfect for EV lithium-ion battery welding.

② Higher Efficiency & Cost Savings

Fiber laser welders consume 30% less energy than arc welding, lowering operational costs.

Automated laser welding robots reduce labor expenses and increase throughput.

③ Eco-Friendly Manufacturing

No filler materials mean less waste, supporting sustainable automotive production.

Lower emissions compared to conventional welding methods.

3. Beginner’s Guide to Laser Welding in Automotive Applications

How Does Laser Welding Work?

A laser welding machine uses a high-intensity laser beam to melt and fuse metals. Common types include:

Recently Posted

-

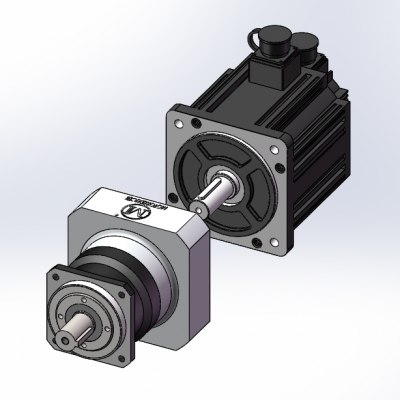

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

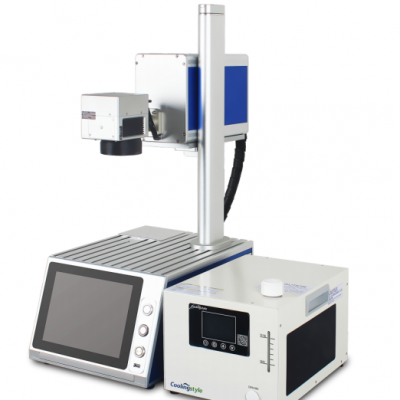

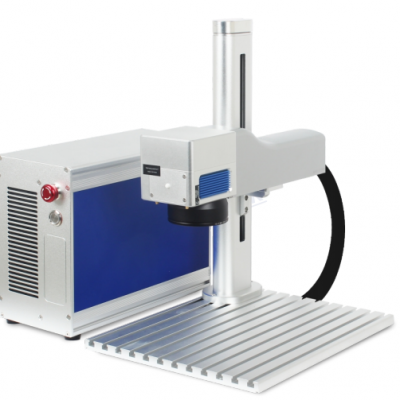

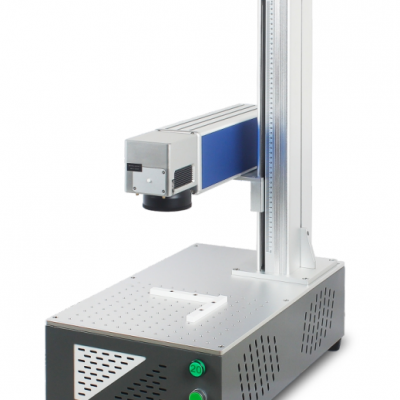

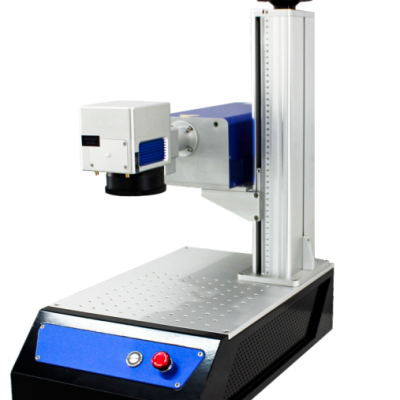

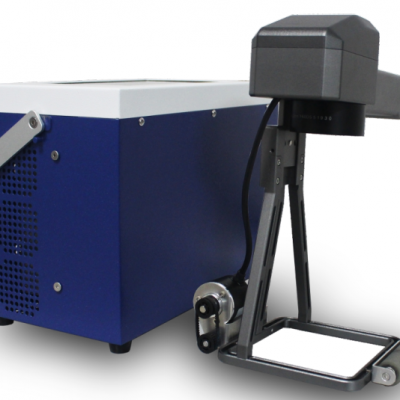

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial Machinery

August 8, 2025The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial MachineryGear reducers (also called gearboxes Read More

Read More