Laser Marking Machines: Masters of Precision in Modern Manufacturing

In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the tiny serial number on the back

of a mobile phone or the clear label on a medical device, the key is a powerful device—a laser marking machine. This article will provide an in-depth understanding

of the working principles, applications, and selection of the right laser marking machine.

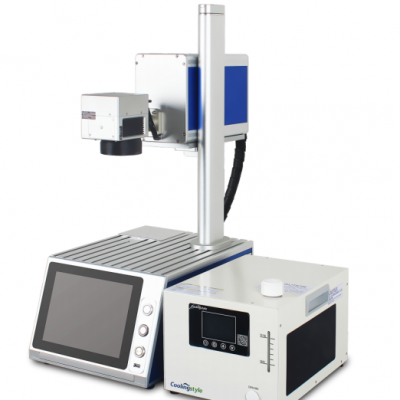

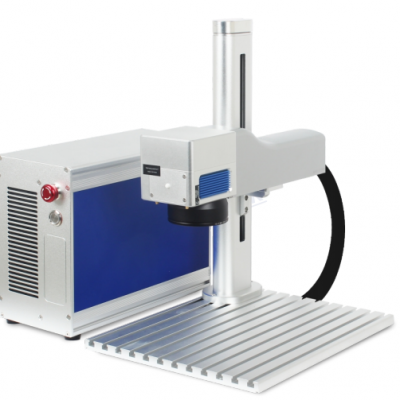

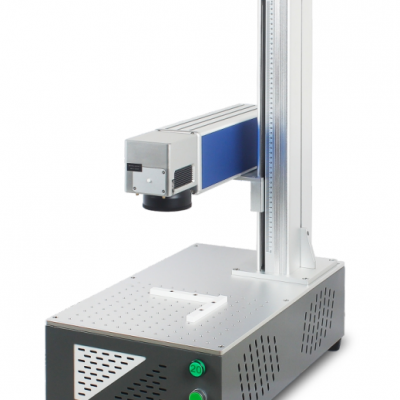

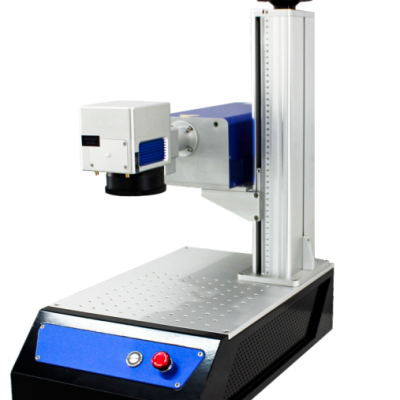

What is a laser marking machine?

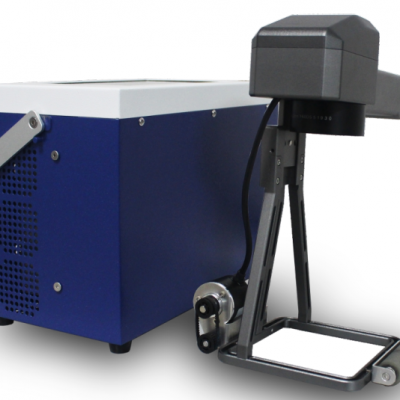

A laser marking machine uses a high-energy laser beam to permanently mark the surface of various materials. By precisely controlling the laser beam's path, it can

engrave complex information such as text, patterns, and QR codes without contacting the surface, thus avoiding mechanical stress or contamination.

How a Laser Marking Machine Works

The core principle of a laser marking machine is selective material removal or surface modification. A laser beam is focused into an extremely fine spot by a focusing lens.

This generates high temperatures on the surface of the material, causing instantaneous vaporization or chemical reaction, leaving a permanent mark. Depending on the

material and the application, the following technologies are primarily used:

Fiber laser marking machines: Suitable for metals and some plastics, they offer high efficiency and a long lifespan.

CO2 laser marking machines: Primarily used for non-metallic materials such as wood, glass, and leather.

UV laser marking machines: For heat-sensitive materials such as certain plastics and electronic components, they enable "cold processing" to reduce thermal effects.

Applications of laser marking machines

Laser marking technology, due to its superior precision and adaptability, is widely used in various industries:

Electronics: Marking circuit boards, chip serial numbers, mobile phone parts, etc.

Medical devices: Permanent identification of surgical instruments and implantable devices to ensure traceability and safety.

Automotive: Marking engine parts, VIN codes, QR codes, etc.

Jewelry and gifts: Personalization with names, dates, or complex patterns.

Food and beverages: Marking packaging with production dates and batch numbers without ink, ensuring environmental friendliness and hygiene.

How to choose the right laser marking machine?

When selecting a laser marking machine, consider the following factors:

Material type: Determine the material you need to mark (metal, plastic, ceramic, etc.) and select a laser with the corresponding wavelength.

Marking Requirements: Select the appropriate laser power and type based on the required depth, speed, and accuracy.

Production Environment: Consider the equipment's stability, maintenance costs, and suitability for integration into existing production lines.

Budget: Fiber laser equipment typically has a higher initial investment but lower maintenance costs, while CO2 laser equipment is more suitable for non-metal processing

and is relatively affordable.

Future Development Trends

With the advancement of Industry 4.0, laser marking machines are becoming increasingly intelligent and connected. Integrating the Internet of Things (IoT) allows these

machines to monitor production data in real time, automatically adjust parameters, and collaborate with other production line equipment. Furthermore, the development

of green laser and ultrafast laser technology will further expand the application of laser marking in precision machining and sensitive materials.

Conclusion

With their unparalleled precision, speed, and flexibility, laser marking machines have become an indispensable tool in modern manufacturing. Whether improving product

traceability or enabling personalized customization, they are quietly driving industry progress. If you are considering introducing laser marking technology, we hope this

guide will provide you with valuable reference!

Recently Posted

-

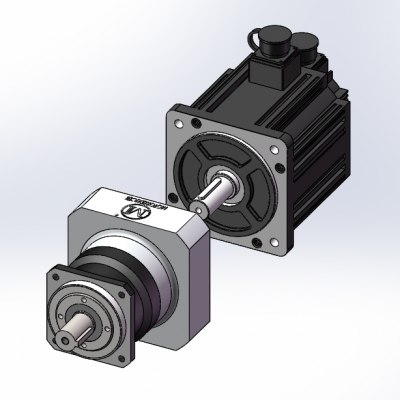

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More -

The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial Machinery

August 8, 2025The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial MachineryGear reducers (also called gearboxes Read More

Read More