The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial Machinery

The Evolution, Modern Applications, and Future Trends of Gear Reducers in Industrial Machinery

Gear reducers (also called gearboxes, speed reducers, or reduction gearboxes) are essential components in industrial machinery,

enabling precise torque control, speed reduction, and power transmission. From early mechanical systems to today’s high-efficiency

models, gear reducers have evolved significantly, enhancing productivity across industries.

The historical development of gear reducers and their impact on industrial machinery.

Modern applications of advanced gear reducers in automation, robotics, and heavy industry.

Future trends, including smart gearboxes, IoT integration, and energy-efficient designs.

Whether you're looking for industrial gear reducers, planetary gearboxes, helical gear reducers, or worm gear motors,

understanding these advancements will help you choose the best solution for your machinery needs.

1. The Evolution of Gear Reducers: A Historical Perspective on Industrial Machinery Development

Early Innovations in Gear Reduction Technology

The concept of gear reducers dates back to ancient civilizations, where wooden gears were used in mills and water wheels.

However, the Industrial Revolution (18th–19th century) marked a turning point with:

Cast iron and steel gears – Improved durability and load capacity.

Standardized gear manufacturing – Enabled mass production for industrial machinery.

Introduction of worm gears and helical gears – Enhanced efficiency and reduced noise.

20th Century: The Rise of Precision Gearboxes

With the growth of automation and heavy industry, gear reducers became more specialized:

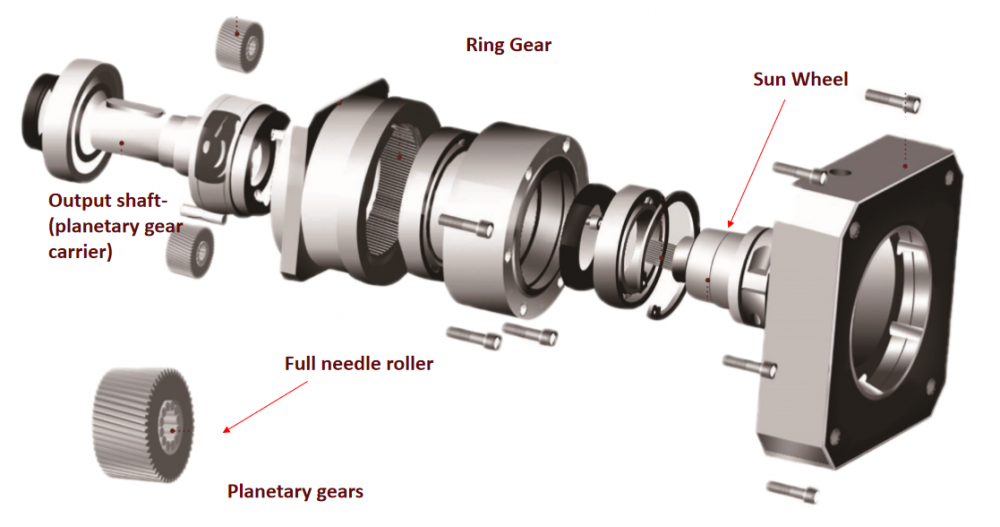

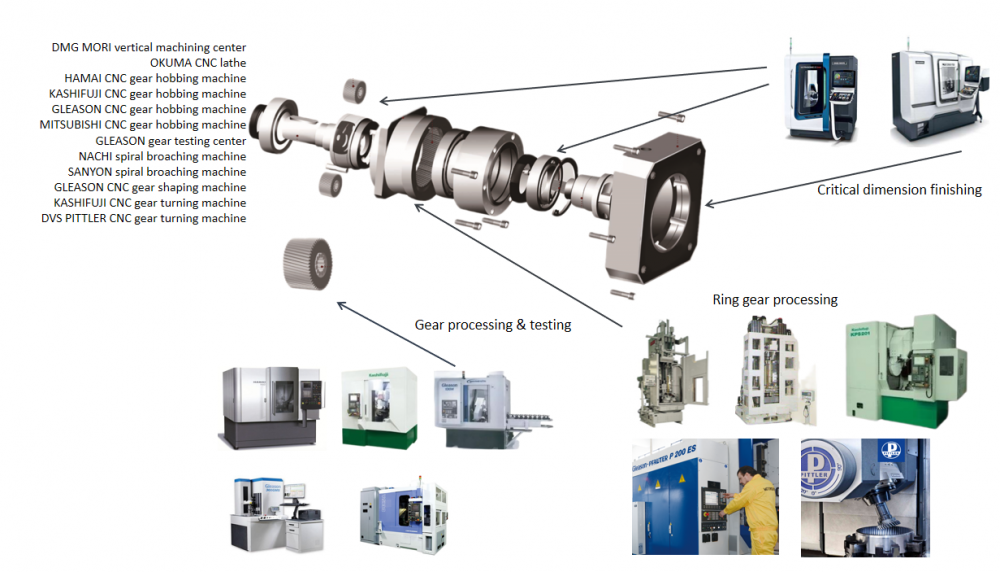

Planetary gearboxes – Offered compact, high-torque solutions for automotive and aerospace applications.

Bevel gear reducers – Improved angular power transmission in mining and construction equipment.

Servo gearboxes – Enabled precise motion control in CNC machines and robotics.

Impact on Industrial Efficiency

The development of high-efficiency gear reducers allowed industries to:

✔ Reduce energy consumption

✔ Increase machinery lifespan

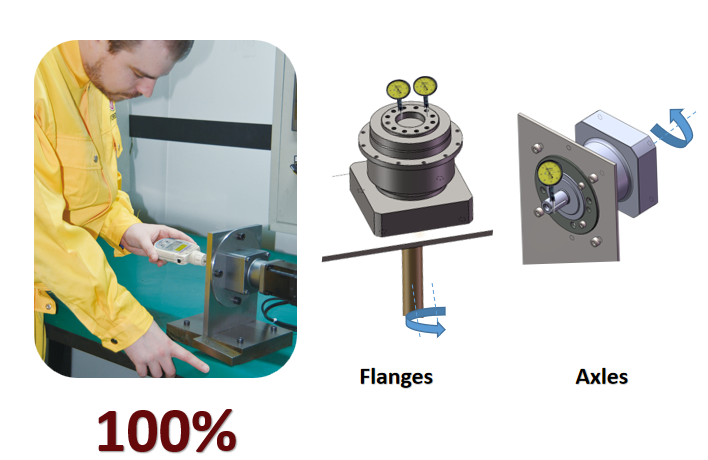

✔ Enhance torque transmission with minimal backlash

Today, manufacturers continue to refine gear reducer designs for heavy-duty, high-speed, and precision applications.

2. Modern Applications of Gear Reducers: Bridging the Gap Between Tradition and Technology

Key Industries Using Advanced Gear Reducers

Modern gear reducers are critical in:

A. Manufacturing & Automation

Robotic arms use precision planetary gearboxes for accurate movement.

Conveyor systems rely on helical gear reducers for smooth, high-torque operation.

B. Renewable Energy

Wind turbine gearboxes require high-torque, low-maintenance designs to withstand extreme conditions.

C. Automotive & Aerospace

Electric vehicles (EVs) use compact gear reducers to optimize motor efficiency.

Aircraft landing systems depend on high-performance gearboxes for reliability.

D. Food & Packaging Machinery

Stainless steel gear reducers meet hygiene standards while ensuring durability.

Case Study: Gear Reducers in Smart Factories

A leading automotive manufacturer integrated IoT-enabled gear reducers with real-time monitoring, reducing

downtime by 30% and maintenance costs by 25%.

3. Future Trends in Gear Reducer Technology: What Lies Ahead for Industrial Machinery?

A. Smart Gearboxes with IoT & AI Integration

Predictive maintenance – Sensors detect wear and prevent failures.

Remote monitoring – Real-time data improves operational efficiency.

B. Lightweight & High-Efficiency Designs

Composite materials reduce weight without sacrificing strength.

Magnetic gear reducers minimize friction, boosting energy savings.

C. Customized & Modular Gear Solutions

3D-printed gearboxes allow rapid prototyping and bespoke designs.

Modular gear systems enable easy upgrades for evolving machinery needs.

D. Increased Demand for Eco-Friendly Gearboxes

Low-noise, high-efficiency reducers align with sustainability goals.

Regenerative drives recover energy in industrial applications.

Conclusion: Choosing the Right Gear Reducer for Your Needs

From worm gear reducers to planetary gear systems, selecting the right gearbox depends on:

Torque & speed requirements

Environmental conditions (dust, moisture, temperature)

Energy efficiency & maintenance needs

As technology advances, smart, efficient, and durable gear reducers will continue to revolutionize industrial machinery.

Looking for high-quality gear reducers? Explore our range of helical, planetary, and worm gearboxes designed for maximum

performance and reliability. Contact us today for a customized solution!

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

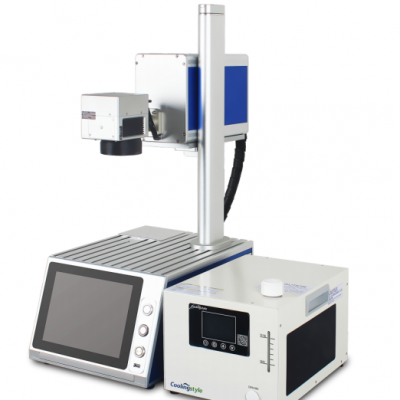

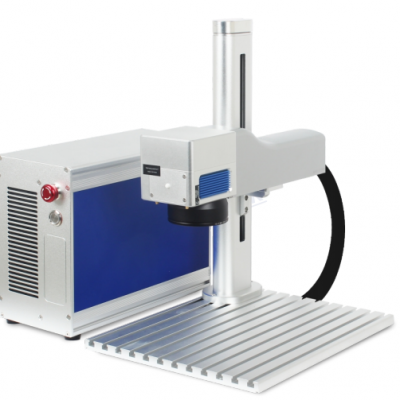

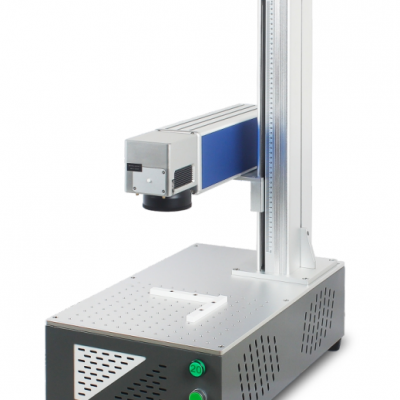

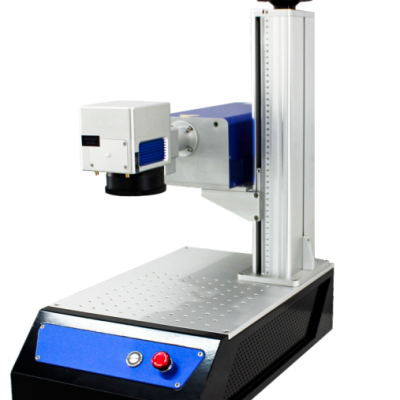

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More