Laser Cutting Technology

Powering Electronics, Metal Fabrication & Renewable Energy Industries

Introduction: The Laser Cutting Advantage in Modern Manufacturing

In today's precision-driven industrial landscape, laser cutting machines have become indispensable across multiple sectors. Offering micron-level accuracy (up to ±5μm), unmatched speed (processing up to 500 parts/hour), and exceptional material versatility, this technology is transforming production floors worldwide.

For B2B manufacturers and engineers, investing in advanced industrial laser cutting systems delivers:

✔ 40-60% faster production throughput

✔ Near-zero material waste with optimized nesting

✔ 30% lower operational costs compared to traditional methods

Let's examine how three critical industries are leveraging laser cutting breakthroughs.

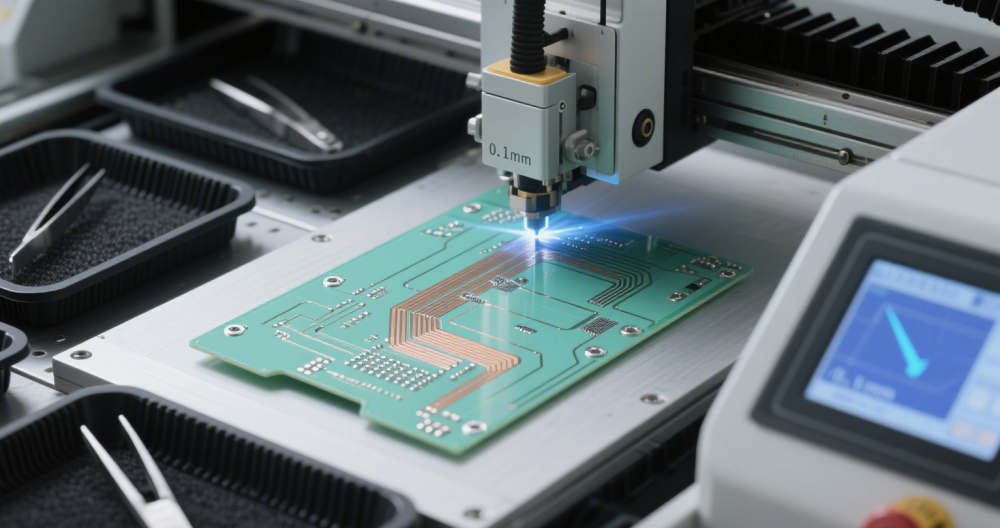

1. Electronics & Semiconductor Manufacturing: Precision at Microscopic Scales

Why Every Top Electronics Manufacturer Uses Laser Cutting

In an industry where a 10μm error can scrap an entire batch, laser cutting provides the perfect solution:

Key Applications:

PCB Manufacturing: Drilling 50μm microvias with CO₂ lasers

Semiconductor Packaging: Cutting silicon wafers with ultra-short pulse lasers

Flex Circuit Production: Processing polyimide films without thermal damage

Case Study: Apple's iPhone Production Breakthrough

Apple's supplier Foxconn implemented UV laser cutting systems to:

Achieve 99.99% cut quality on stainless steel chassis

Reduce component rejection rates by 75%

Enable 15% thinner device designs

Technical Advantages for Electronics:

Non-contact processing prevents material stress

Burr-free edges eliminate post-processing

Automated vision systems ensure perfect alignment

2. Metal Fabrication: The Quiet Revolution in Sheet Metal Processing

How Laser Cutting is Redefining Modern Metal Workshops

From architectural metalwork to industrial machinery, laser systems deliver:

Transformational Benefits:

Cut 20mm stainless steel at 2m/min

Nest parts with 95% material utilization

Process 10x faster than plasma cutting

Customer Testimonial: Boeing Supplier Success Story

Aerospace metal supplier Precision Machined Products achieved:

$1.2M annual savings on aluminum parts

60% faster job changeovers

Zero tooling costs for custom orders

Industry-Specific Solutions:

Hardware Manufacturing: Cut 500 hinges/hour with perfect consistency

HVAC Systems: Process galvanized steel ducts without zinc damage

Industrial Equipment: Fabricate 3D welded assemblies from flat patterns

ROI Calculation:

Most metal fabricators recoup their fiber laser investment in <18 months through:

✔ 50% labor cost reduction

✔ 30% lower energy use vs competitors

✔ 15% higher customer retention from superior quality

3. Renewable Energy: Laser Cutting Fuels the Green Transition

Powering Solar, Wind & Hydrogen Technologies

The renewable energy sector demands high-volume precision - exactly what laser cutting delivers:

Breakthrough Applications:

Solar Panel Production:

☞ Cut thin-film solar cells with <0.1mm kerf

☞ Process 30% more panels per hour than mechanical methods

Wind Turbine Components:

☞ Fabricate 20m turbine blades with perfect airfoil profiles

☞ Cut composite materials without delamination

Hydrogen Fuel Cells:

☞ Machine bipolar plates with 50μm flow channels

☞ Achieve leak-proof seals in stainless steel stacks

Infographic: Laser Cutting's Role in Clean Energy

Sustainability Benefits:

70% less material waste than stamping

Zero lubricants/coolants required

50% energy savings vs traditional cutting

Choosing Your Ideal Laser Cutting Solution

For B2B buyers evaluating systems, consider:

1. Technology Match

✓ Fiber lasers for metals (1-30mm)

✓ UV lasers for electronics (ultra-fine)

✓ CO₂ lasers for organics (plastics, wood)

2. Production Volume

✓ 3kW systems for job shops

✓ 6kW+ systems for high-volume

✓ Automated cells for 24/7 operation

3. Smart Features

✓ AI nesting software

✓ Predictive maintenance

✓ Remote monitoring

Why Global Manufacturers Trust Our Laser Solutions

✔ 500+ installations worldwide

✔ Industry-leading <0.5% downtime

✔ Turnkey integration support

Please contact me: https://www.modolycn.com/page/contactus/index.php

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

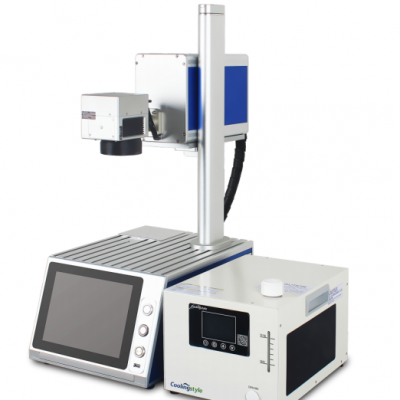

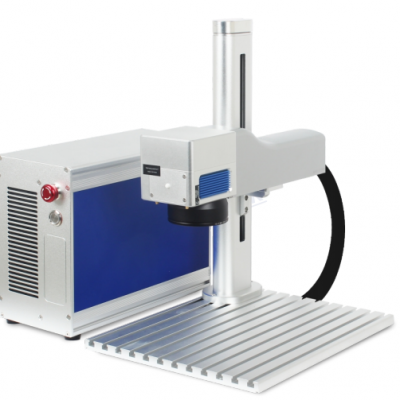

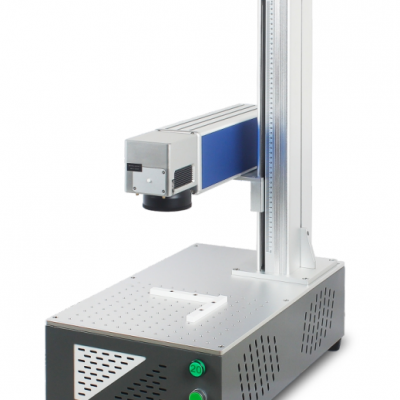

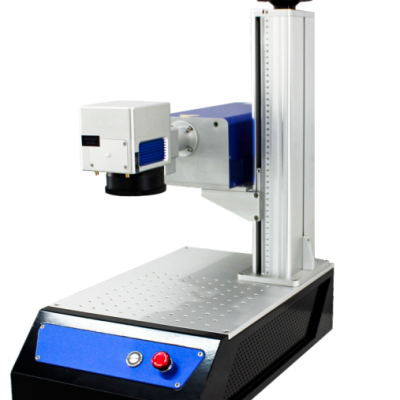

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More