The Critical Role of Planetary Gearboxes in Advancing Medical Devices

Precision Engineering for Enhanced Patient Care

Introduction

In the rapidly evolving field of medical technology, planetary gearboxes have emerged as a cornerstone of precision engineering, enabling breakthroughs in surgical robotics, diagnostic imaging, and patient care automation. This article explores how high-precision planetary gear systems enhance medical device performance, examines their role in next-generation healthcare solutions, and provides key insights for medical device manufacturers selecting the right gearbox technology.

1. How Planetary Gearboxes Improve Medical Device Functionality & Reliability

Enhancing Precision in Surgical Robotics

Planetary gear reducers are integral to robot-assisted surgical systems, such as the da Vinci Surgical System, where they provide:

Sub-micron positioning accuracy for delicate incisions and suturing

Smooth torque transmission with near-zero backlash to prevent jerky movements

Compact, high torque density for minimally invasive robotic arms

Optimizing Medical Imaging Equipment

In MRI machines, CT scanners, and X-ray systems, planetary gearboxes ensure:

Vibration-free rotation of heavy gantries for clear image capture

Precise angular control in C-arms and patient positioning systems

Long-term reliability with medical-grade lubrication for continuous operation

Case Study: Prosthetics & Exoskeletons

Advanced bionic limbs and rehabilitation exoskeletons use low-backlash planetary gears to:

Mimic natural joint movements with adaptive torque control

Support AI-driven gait analysis for personalized physical therapy

2. The Future of MedTech: Why Planetary Gearboxes Are Essential for Next-Gen Healthcare

Key Trends Driving Adoption

Telemedicine & Remote Surgery: Robotic systems with high-response planetary gear motors enable surgeons to operate remotely with haptic feedback.

AI-Powered Diagnostics: Automated lab equipment relies on precision gear reducers for consistent sample handling.

Wearable Medical Devices: Compact planetary gear systems enhance insulin pumps and smart inhalers.

Innovation Spotlight: Micro-Surgical Robots

Emerging nanoscale surgical bots use miniature planetary gearboxes (under 10mm) for:

Ophthalmic surgery (e.g., retinal vein cannulation)

Neurosurgery (e.g., tremor-free electrode placement)

3. Planetary Gearbox Design: What Medical Device Manufacturers Must Know

Critical Design Considerations

Factor Medical Industry Requirement

Backlash <1 arcmin for surgical robotics

Material Stainless steel (ISO 5832-1) or ceramic-coated components

Sterilization Autoclavable or gamma-ray-resistant housings

Noise Level <45 dB for patient comfort

Certification ISO 13485, FDA Class II/III compliance

Selection Best Practices

Load Analysis: Calculate peak torque in prosthetic knee joints or imaging system rotors.

Cleanroom Compatibility: Opt for sealed, lubricant-free designs for IVD (In Vitro Diagnostic) equipment.

Lifecycle Testing: Simulate 10+ years of sterilization cycles and high-duty operation.

Real-World Example: Ventilator Motor Drives

During COVID-19, medical-grade planetary gearboxes ensured reliable flow control in ventilators by:

Maintaining precise RPM under variable air resistance

Withstanding 24/7 operation without lubrication breakdown

Conclusion: Planetary Gearboxes as Catalysts for Medical Innovation

From robot-assisted surgery to portable dialysis machines, planetary gear systems are redefining healthcare standards through:

✔ Unmatched precision for life-critical applications

✔ Miniaturization enabling less invasive treatments

✔ Smart integration with AI and IoT-based MedTech

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

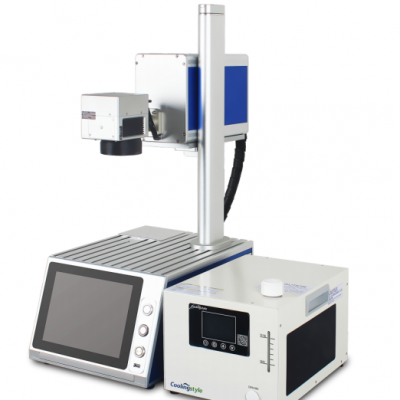

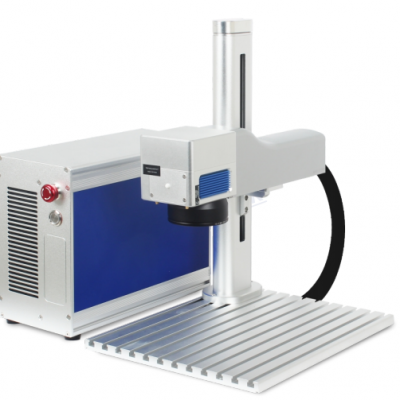

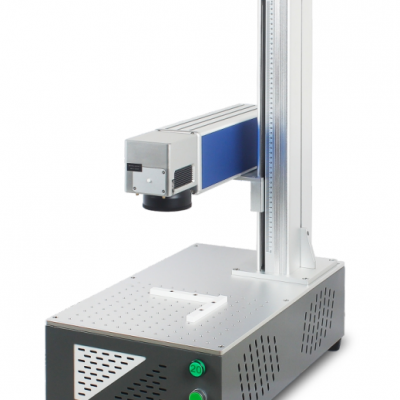

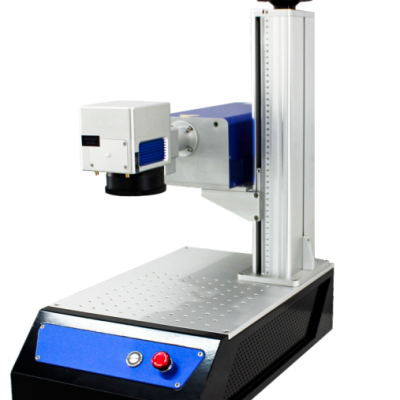

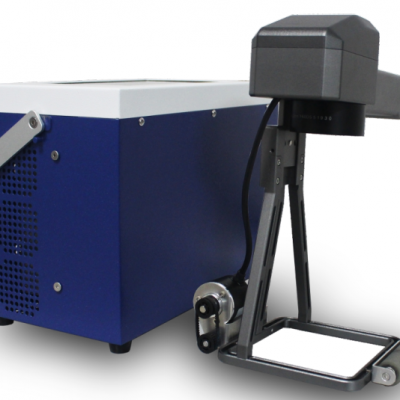

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More