Laser welding machine: efficient and precise welding solution for modern manufacturing industry

In today's rapidly developing manufacturing industry, welding technology, as a key link in product manufacturing, directly affects product

quality and production efficiency. Traditional welding methods have gradually failed to meet the needs of high-precision and high-efficiency

modern manufacturing, and laser welding technology is becoming a new favorite in the industrial field with its unique advantages.

This article will comprehensively analyze the core advantages, purchase guides and cross-industry applications of laser welding machines,

and take you to a deep understanding of how this revolutionary technology reshapes modern manufacturing.

Five core advantages of laser welding machines

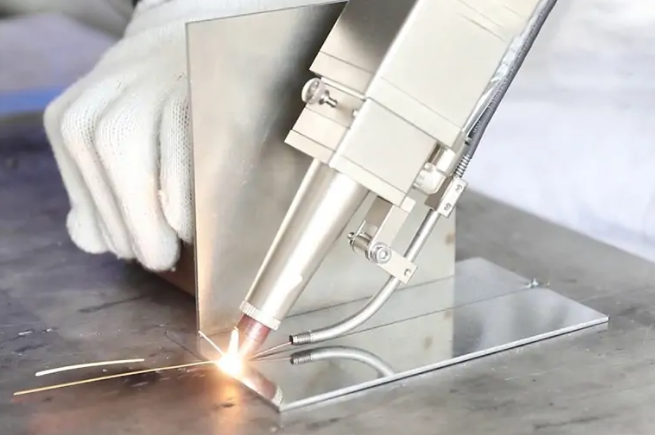

1. Ultra-precision welding capability

The spot diameter of laser welding can be as small as 0.1mm, achieving precision processing that is difficult to achieve with traditional

welding:

Micron-level precision: suitable for welding of micro-components such as electronic components and medical devices

Small heat-affected zone: reduce material deformation and maintain the original mechanical properties of the workpiece

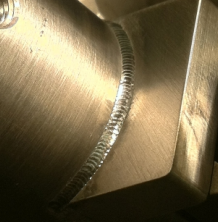

Beautiful weld: no secondary grinding is required, improving product appearance quality

Case comparison: welding of the middle frame of a smartphone, the yield rate of traditional argon arc welding is only 82%,

which is increased to 99.5% after laser welding

2. Revolutionary improvement in production efficiency

The welding speed can reach 10m/min, which is 5-8 times that of MIG welding

No welding materials required: save 20-30% of consumables cost

Instant switching: quickly adjust parameters through software to adapt to different product requirements

3. Significant comprehensive cost advantage

Cost item Laser welding Traditional welding

Labor cost Low High

Energy consumption 3kW/h 8kW/h

Post-processing No Need

Equipment life 100,000 hours 50,000 hours

4. Wide range of material adaptability

Weldable materials include:

Conventional materials: carbon steel, stainless steel, aluminum alloy

Special materials: copper alloy, titanium alloy, dissimilar metal combination

Thin plate material: 0.1mm ultra-thin plate without deformation welding

5. Intelligent and automated integration

Can seamlessly connect to robotic arms and automated production lines

Equipped with visual positioning system to achieve intelligent identification welding

Data traceability function, support for digital management of Industry 4.0

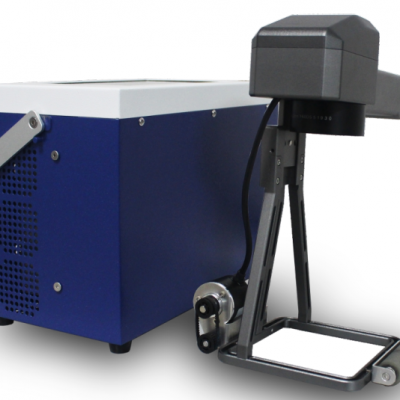

Ultimate guide to purchasing laser welding machines

1. Determine core demand indicators

Power selection:

Below 500W: electronic precision welding

1-3kW: general industrial welding

Above 6kW: deep melting welding of thick plates

Comparison of laser types:

Type Fiber laser CO₂ laser Pulsed laser

Wavelength 1070nm 10.6μm 1064nm

Efficiency 30-50% 10-15% 5-10%

Maintenance cost Low High Medium

Applicable scenarios Metal welding Non-metal Spot welding

2. Key configuration checklist

Cooling system: dual-circulation water cooling system is preferred

Optical lens: imported coated lens life is extended by 3 times

Control system: at least equipped with a 7-inch touch screen

Safety certification: must pass CE and FDA certification

3. Supplier evaluation dimensions

Technical strength: whether it has independent research and development capabilities

After-sales service: whether the response time is promised within 24 hours

Case experience: the number of successful cases in the same industry

Training support: whether free operation training is provided

4. Budget planning suggestions

Entry-level: 150,000-300,000 (domestic fiber laser)

Industrial level: 500,000-800,000 (imported core components)

Top configuration: 1 million+ (fully imported automation system)

Eight major industry applications of laser welding machines

1. Automobile manufacturing

Battery welding: sealing welding of new energy battery modules

Body welding: laser welding of aluminum alloy doors

Components: 40% increase in welding strength of turbochargers

2. Consumer electronics industry

Mobile phone middle frame: 0.3mm stainless steel seamless welding

Earphone diaphragm: micron-level precision spot welding

PCB board: welding of components without heat damage

3. Medical device manufacturing

Surgical instruments: aseptic welding of 316L stainless steel

Implants: surface treatment of titanium alloy bone screws

Dental equipment: welding of precious metal crowns and bridges

4. Aerospace applications

Engine blades: nickel-based alloy repair welding

Fuel tank: aluminum alloy space curve welding

Satellite components: space-level reliability verification

5. Home appliance manufacturing

Compressor: copper tube brazing replaces traditional processes

Washing machine inner drum: 0.5 seconds/piece high-speed welding

Air conditioning heat exchanger: 100% airtightness guarantee

6. Hardware tools

Tools: Welding of carbide and steel substrate

Locks: One-time molding of anti-disassembly structure

Bathroom: No-leak welding of faucets

7. New energy field

Photovoltaic: Silicon wafer string welding efficiency increased by 300%

Hydrogen energy: Fuel cell bipolar plate welding

Energy storage: Battery pack automated welding line

8. Rail transit

Car body: Continuous laser welding of stainless steel car body

Bogie: Deep fusion welding of high-strength steel

Pantograph: Welding of copper alloy conductive parts

Future development trend

Composite welding technology: Laser-arc composite welding will become the mainstream of thick plate welding

Green manufacturing: Energy-saving equipment research and development that reduces energy consumption by another

30%

AI intelligence: Self-learning welding parameter optimization system

Ultrafast laser: Picosecond laser welding expands to a wider range of materials

Laser welding technology is reshaping the quality and efficiency standards of modern manufacturing. Whether it is to increase the yield rate by 0.1% or save 30% of production costs, choosing the right laser welding solution will bring significant competitive advantages to enterprises. It is recommended that enterprises should consider current production needs and reserve space for future technology upgrades when selecting equipment.

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

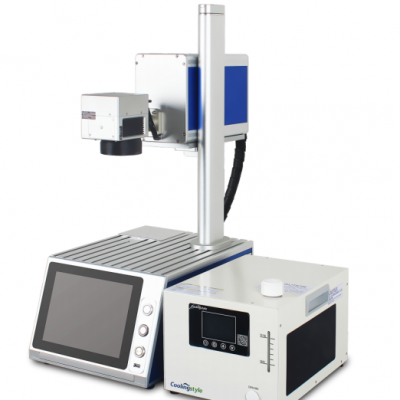

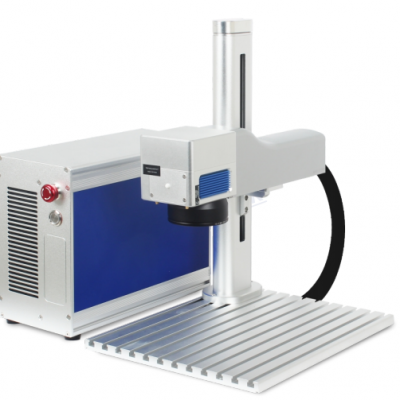

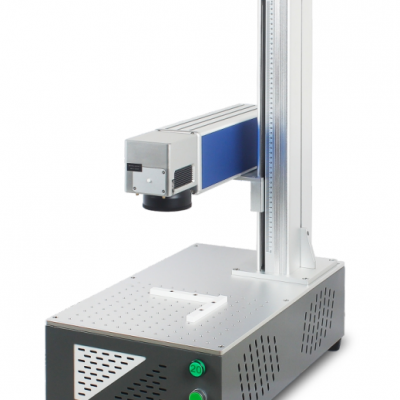

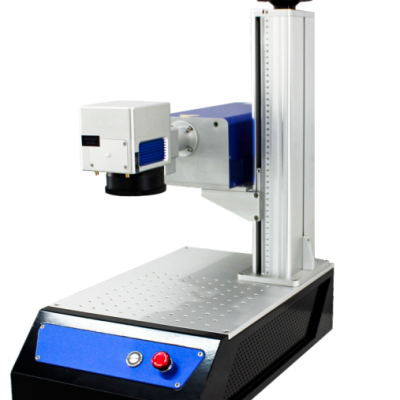

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More