Planetary reducers: a revolutionary solution for industrial equipment efficiency and performance

In modern industrial manufacturing, efficient and reliable transmission systems are the key to ensuring stable operation of equipment. Planetary reducers, as a high-precision, high-torque transmission device, are being widely used in robots, machine tools, packaging machinery and other fields around the world. This article will explore the technical advantages of planetary reducers, practical application cases, and how to choose the right reducer model to help you fully understand how this revolutionary technology can improve the performance and efficiency of industrial equipment.

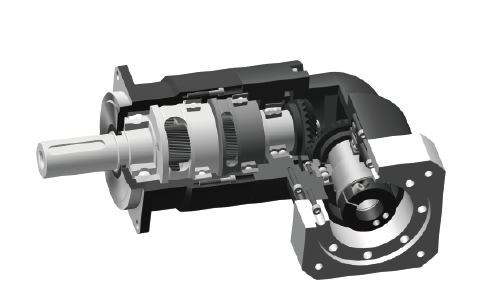

Technical advantages of planetary reducers

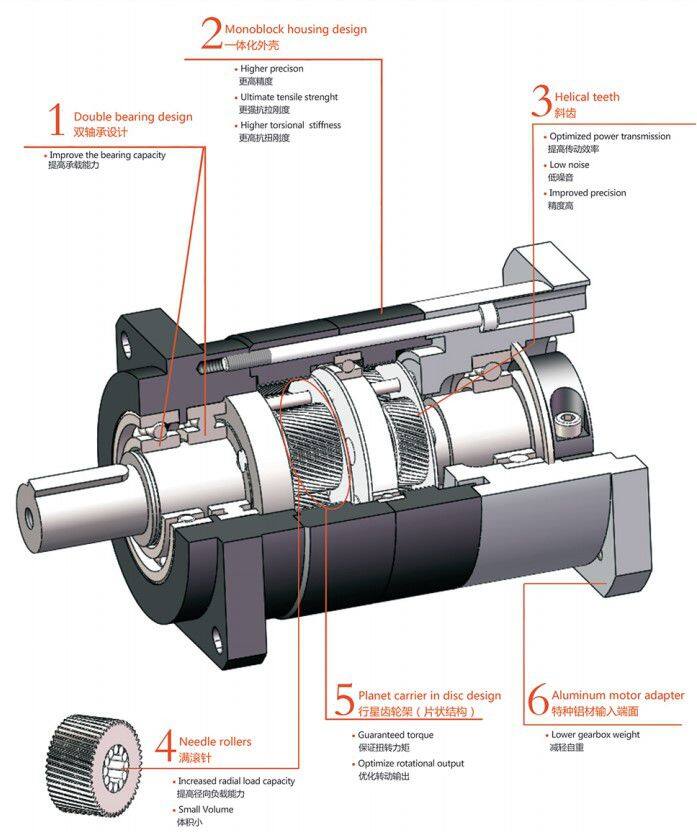

1. High precision and smooth transmission

Planetary reducers adopt helical gear design, which has the following significant advantages:

Good toothing: smooth transmission, low noise, suitable for environments with high requirements for quietness.

Large overlap: Reduces single tooth load and extends gear life.

High-precision processing: The gear material is SCM415, and after rigorous processes such as tempering, carburizing, and grinding, the tooth surface hardness reaches 60±2HRC, and the accuracy is controlled within DIN6 level.

In addition, the Motoli planetary reducer adopts the "K" type tooth repair method to further reduce the friction torque and optimize the life cycle of the gear system. The vibration value is only 1/4 of other reducers

2. High torque and high rigidity

The structural design of the planetary reducer enables it to withstand high loads:

Optimize the force point: Reduce local stress concentration through balanced design.

High-strength material: The transmission parts are made of chromium-manganese steel, combined with forging technology to enhance toughness and rigidity

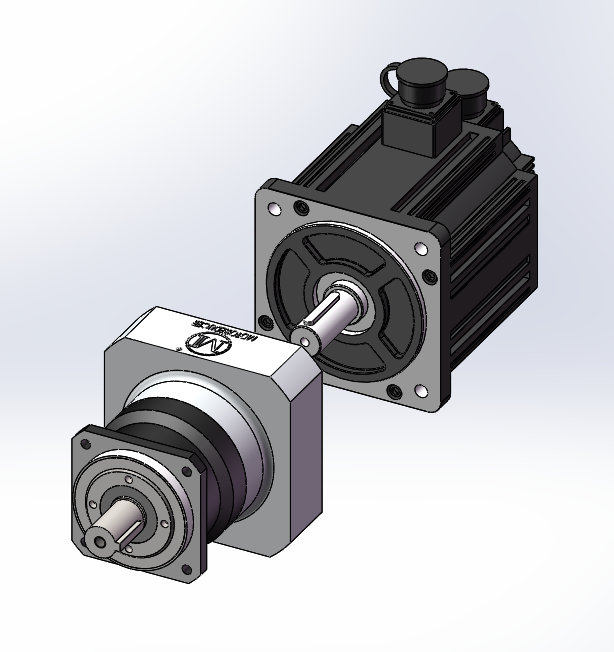

3. Compact design and diversified speed ratios

The modular design of the planetary reducer makes it compact and suitable for space-constrained application scenarios. The speed ratio range is wide (3-100), and the best configuration can be selected according to different working conditions:

Speed ratio 10: suitable for continuous operation, but the forward and reverse performance is weak

Speed ratio 5.5: Perfect balance between torque and frequent forward and reverse requirements, using a four-planet gear support design

Speed ratio 3: suitable for frequent forward and reverse rotation, but the torque output is low

Practical application cases of planetary reducers

1. Robotics

Delta robot (parallel robot): requires low inertia (speed ratio 7-10) and high torque output (speed ratio 4 or 5.5), and common combinations are 7×4=28 or 8×5.5=44

Robotic arm (Pick & Place): MPVB series reducers perform well in blow molding machines, achieving fast and accurate grasping

2. Machine tools and processing equipment

Panel bending machine: High-rigidity reducers are used to ensure bending accuracy

Pipe bending machine: Reducers are used in machine heads, feeding mechanisms and gear rack transmissions to improve processing efficiency

3. Packaging and textile machinery

Diaper production line: Each device is equipped with 66 reducers, the manufacturing unit rotates continuously, and the packaging unit runs alternately.

Drum spinning machine: MVB series reducers provide stable power to ensure yarn quality.

4. New energy and special equipment

Solar panel production line: reducers are used for precise positioning and rotation control.

Tire building machine: MVD series reducers are suitable for high-intensity and high-frequency working environments

How to choose a suitable planetary reducer

1. Determine key parameters

The following factors should be considered when selecting:

Load torque: Calculate torque based on equipment requirements.

Speed ratio: Determine based on input/output speed.

Working environment: temperature, heat dissipation conditions and load type (continuous or intermittent).

2. Comparison of mainstream series

Series Torque range (Nm) Speed ratio Backlash (arcmin) Applicable scenarios

MVB/MVE 14-1900 3-100 3-5 High precision, high rigidity

5MVB/5MVE 40-360 3-100 3-5 Highest precision and torque

MAF 14-3150 4-100 3-5 Harsh working conditions, high load

MPVB/MPVE 34-360 3-100 5-8 Economical, medium precision requirements

3. Calculation example

Reducer torque: Torque = 9550 × Motor power ÷ Input speed × Speed ratio × Use factor

Motor power: Power = Torque × 9550 ÷ Input speed ÷ Speed ratio ÷ Use factor

Conclusion

Planetary reducers are becoming the core components of industrial equipment upgrades with their high precision, high torque and compact design. Whether it is a robot, machine tool or packaging machinery, choosing the right reducer can significantly improve efficiency and reduce maintenance costs. The cooperation between MOTOLI Transmission and RECKON DRIVES of France has further promoted the innovation and development of this technology. In the future, with the deepening of industrial automation, planetary reducers will continue to lead the revolution of transmission technology.

For more selection suggestions or technical details, please contact us for professional support!

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

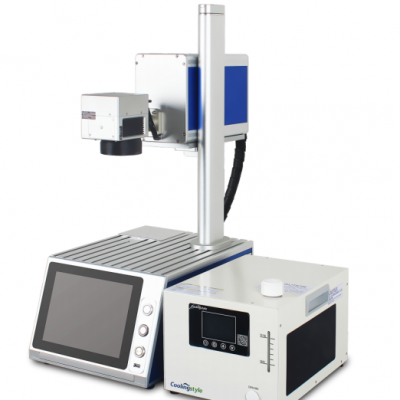

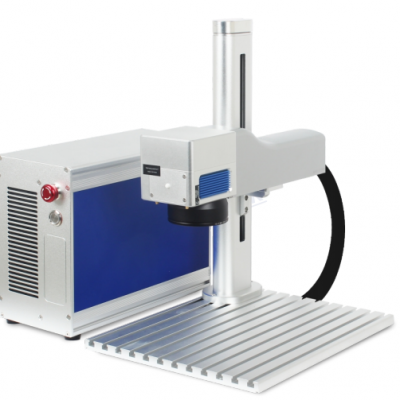

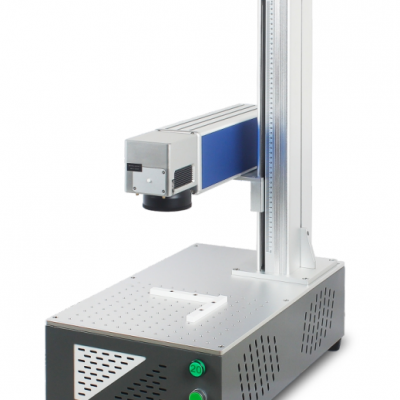

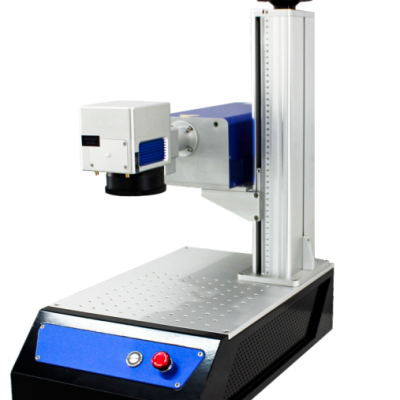

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More