High-efficiency transmission solution: the ultimate choice for 30% energy saving

MODOLYCN

Why must modern factories upgrade their reducers?

In the era of intelligent manufacturing, the energy efficiency of industrial equipment directly determines the competitiveness of enterprises. The common problems of low efficiency and frequent maintenance of traditional reducers are costing many factories. The GX series of high-precision reducers newly launched by the XX brand, using revolutionary double helical gear technology, has helped 32 manufacturing companies achieve:

✔️ Average energy consumption reduced by more than 30%

✔️ Maintenance interval extended to 8,000 hours

✔️ Overall equipment efficiency (OEE) increased by 18%

5 major pain points and breakthrough solutions of traditional reducers

Pain point 1: Low transmission efficiency

Industry status: Ordinary reducers have energy losses of 15-20%

solution: Patented double helical gear design, efficiency increased to 98.5%

Pain point 2: Vibration and noise exceed the standard

Typical problem: Working noise > 85 decibels, affecting workers' health

Our innovation: Flexible bearing system + shock-absorbing housing, noise reduced to 72 decibels

(Insert noise comparison test video link)

Pain point 3: Insufficient sealing performance

Common faults: Oil leakage repair 3-5 times a year

Technical breakthrough: Triple labyrinth seal, IP67 protection certification

Pain point 4: Slow customization response

Industry standard: Delivery time is usually 4-6 weeks

Our advantage: Modular design, conventional models are shipped within 72 hours

Pain point 5: Low degree of intelligence

Realistic dilemma: Failures cannot be predicted

Smart solution: Optional IoT sensors to monitor operating status in real time

Typical application cases

BYD new energy vehicle battery production line

Before transformation:

16 hours of downtime per month due to reducer failure

Annual maintenance cost 480,000 RMB

Penalty for excessive energy consumption

Use less energy to get stronger power, longer service life and lower overall operating costs!

Anything you want know more check my website: www.modolycn.com

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

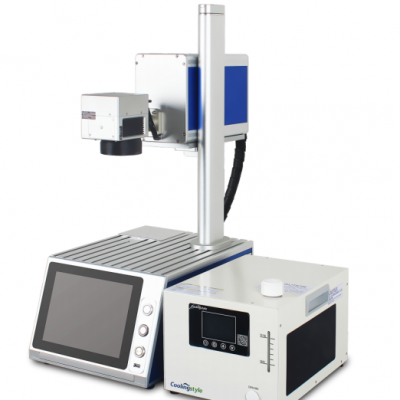

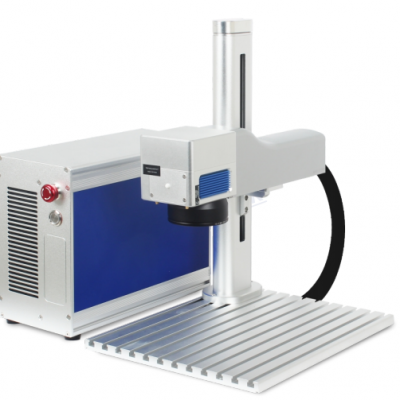

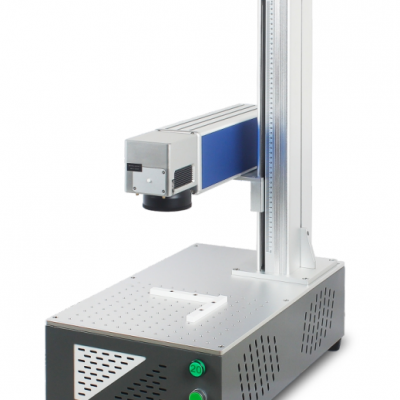

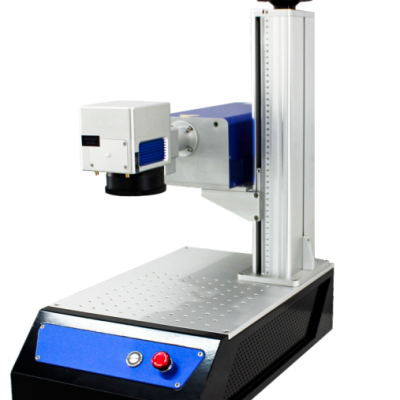

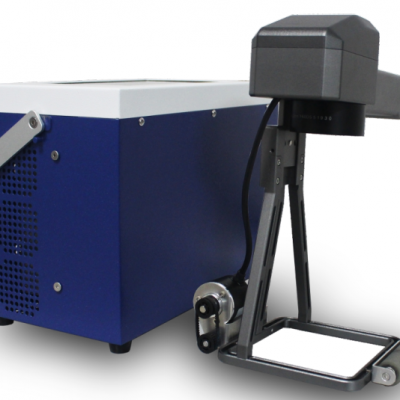

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More