Precision solutions for modern industry

Precision solutions for modern industry

How laser technology revolutionizes traditional welding processes

In today's rapidly developing manufacturing industry, laser welding technology is gradually replacing traditional welding methods with its high precision, high efficiency and environmental protection characteristics.

Comparative advantages of laser welding over traditional welding

1. Unparalleled precision control

Laser welding technology can achieve 0.1mm level welding accuracy, which is difficult to achieve with traditional welding methods. Modoly's handheld welding equipment is specially designed with a precision control system, which can perfectly weld even complex curves and tiny parts.

2. Significantly improved production efficiency

The laser welding speed can reach 5-10 times that of traditional welding, and no subsequent processing is required, which greatly shortens the production cycle. German partners reported that the average production efficiency of companies using Modoly equipment has increased by 300%.

3. Environmental protection and energy saving characteristics

Compared with traditional welding, laser welding reduces energy consumption by 40%, has no harmful gas emissions, and fully meets the green environmental protection requirements of modern manufacturing industry.

3-in-1 basic model

Welding + cutting + cleaning basic functions

Suitable for small processing plants and repair shops

Power range: 1000W-1500W

Cost-effective choice

4-in-1 advanced model

Adding grinding function on the basis of 3-in-1

Suitable for medium-sized manufacturing enterprises

Power range: 1500W-2000W

Standard intelligent temperature control system

5-in-1 professional model

Full functions of welding + cutting + cleaning + grinding + engraving

Meet high-end manufacturing needs

Power range: 2000W-3000W

Optional automation interface

Core advantage:

Modular design: functions can be flexibly combined according to needs

Intelligent adjustment system: automatically matches different material parameters

Safety protection: multiple protection mechanisms ensure safe operation

Durable structure: industrial-grade components, long service life

Practical application scenarios

1.Metal processing industry

Welding of stainless steel products

Aluminum alloy frame connection

Precision processing of copper parts

2.Equipment maintenance field

Mechanical parts repair

Mold maintenance

On-site emergency repair

3.Electronic manufacturing

Precision component welding

Micro parts processing

Sensor assembly

Recently Posted

-

Partner with a Trusted Planetary Gearbox Supplier for Your Equipment Store

September 9, 2025Are you a global machinery or equipment supplier looking to expand your product offerings and meet the growing demand for precisio Read More

Read More -

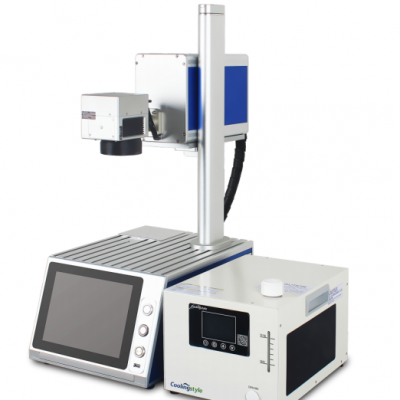

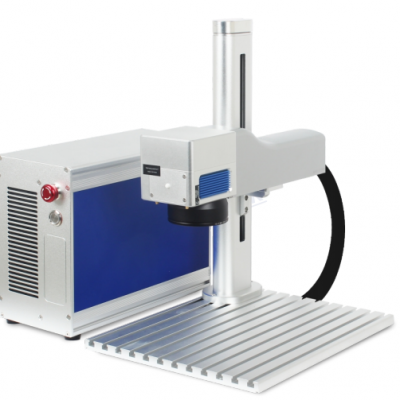

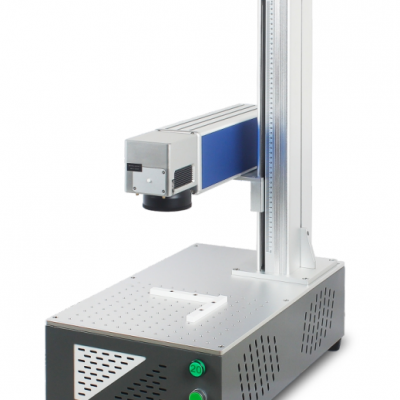

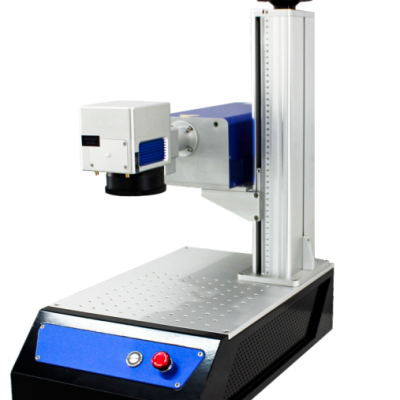

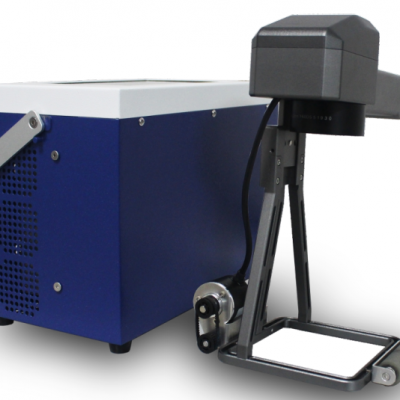

Laser Marking Machines: Masters of Precision in Modern Manufacturing

August 22, 2025In modern manufacturing, precise, efficient, and permanent marking has become an indispensable requirement. Whether it's the t Read More

Read More -

Key Applications of Planetary Gearboxes in Automated Production Lines

August 18, 2025A Guide to Optimizing Conveying, Sorting, and Assembly SystemsIntroductionIn modern intelligent manufacturing, automated productio Read More

Read More -

How Laser Welding Machines are Revolutionizing the Automotive Industry

August 11, 2025The automotive industry is undergoing a massive transformation, driven by advancements in laser welding technology. As manufa Read More

Read More